SiSTEM Technology is a highly regarded sales, distribution and service solutions company, supplying a comprehensive range of semiconductor manufacturing equipment from lab to fab for today’s and tomorrow’s technologies.

SiSTEM Technology offer one of the largest ranges of cutting-edge process tools, ancillaries, automation solutions, inspection and test equipment, along with consumables to the semiconductor, microelectronics, and other high technology industries in the United Kingdom, Europe and the Nordic countries. Our expertise spans from supporting projects in the research and development phase, to assisting with pilot lines, as well as enabling full-scale production. We have a commitment to excellence, and are your solutions partner no matter the size or scope of your project. Many of our principals are world leaders in their respective fields, and bring vast expertise and knowledge to make sure you deliver reliable and consistent results from complex processes, through collaboration throughout the sales process.

SiSTEM Technology provide solutions for:

- Atomic Layer Deposition

- Physical Vapour Deposition (PVD)

- Chemical Vapour Deposition (CVD)

- Ion Beam Milling & Etch

- Diamond-Like Carbon

- Indium Evaporation

- Photo Processing

- Spin Coat, Develop & Clean | Bake/Chill

- Temporary Bond & Debond

- Mechanical or Thermal Debond

- Wet Processing

- Wet Benches | Single Wafer Spin Spray Processing

- Optical Defect Inspection

- Microelectronics Reliability Testing

- Probe, Test & Burn-In

- Wafer & Reticle Handling & Automation

- Sorters & EFEMs | Open-Cassette to SMIF Retrofit | SMIF Pod Load & Unload | Reticle Storage Systems | 450mm FOUP | EUV Pod Openers | 300mm AGV/Stocker | Mass Wafer Transfer Systems

- High Purity Chemical & DI-Water Heaters

- Megasonics

- Single Wafer | Batch

- Thermal Cure Ovens

- Thermal Vacuum Chambers (TVAC)

- Consumables

- Chuck Cleaning Wafers

- Vacuum Traps & Filters

- OEM Diffusion Furnace Elements (Horizontal & Vertical)

- Ceramic Vacuum Formed Heaters & Insulation Shapes

- FFKM & FKM O-Rings & Seals

Atomic Layer Deposition

We work with our partner Picosun, an Applied Materials company. Picosun’s ALD technology offers precise, conformal, and high-quality thin-film deposition capabilities across a wide range of materials. Its advanced process control, scalability, and support services make it a valuable choice for researchers and industries requiring precise and reliable thin-film coatings.

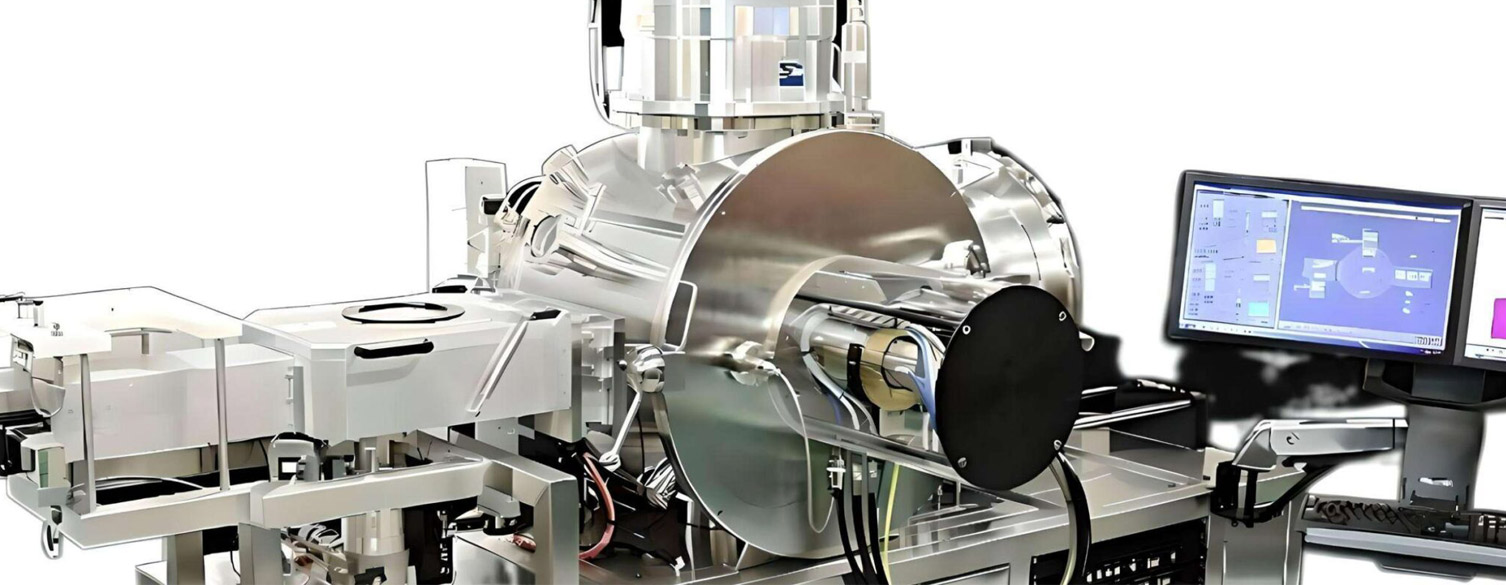

Thin Film

Intlvac Thin Film design, engineer and manufacture a wide variety of customised systems for Thin Film PVD and Etch. Their product line ranges from small R&D/pilot project systems to large production systems utilising processes such as Ion Beam Etching, Sputtering, Electron Beam Evaporation and Thermal Evaporation fibre-optic coating and more.

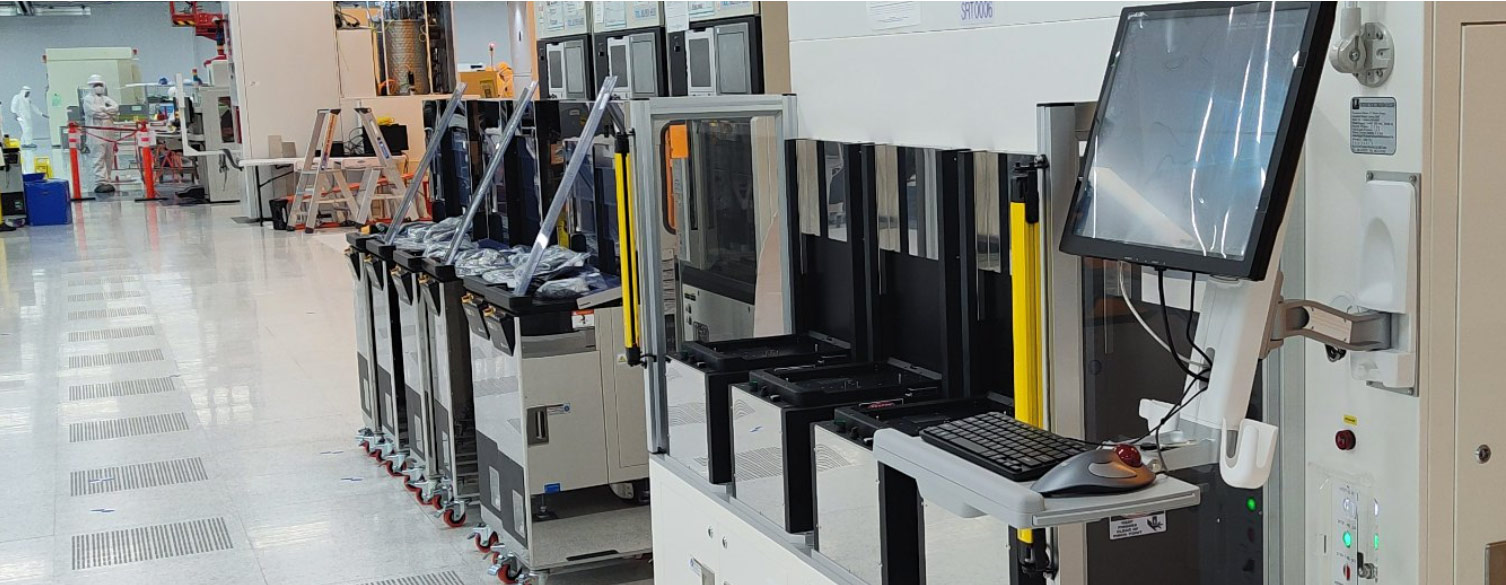

Wafer & Reticle Handling & Automation

Fortrend handling and automation equipment comprises retrofit open-cassette tools to SMIF pod load/unload systems, sorters and EFEMs, mass wafer & reticle transfer systems, reticle storage and handling systems, and robots & robotic arms.

Photolithography Solutions

Cost Effective Equipment (CEE) is a leader in high-precision wafer process instruments for demanding applications. From compact bench-top tools to the fully integrated X-Pro II Workstation, CEE caters for a wide range of needs and uses, with multiple customisation options.

Optical Defect Inspection

Nanotronics optical defect inspection solutions encompass a diverse lineup of cutting-edge products that integrate high-resolution imaging, artificial intelligence, and automation. These solutions provide precise, dependable, and streamlined inspection capabilities, ensuring accurate and efficient defect detection.

Wet Processing

CSTI/Kemsafe specialises in providing tailored solutions for critical wet processes, such as cleaning, etching, and stripping, ensuring precision and reliability at every stage. The company’s innovative equipment portfolio includes wafer cleaning systems, chemical delivery units, and advanced wet benches, all designed to enhance productivity, reduce contamination, and improve overall yield.

Reliability Testing

Our partner ELES offer reliability testing solutions that encompasses a range of techniques and methodologies designed to simulate real world operating conditions, stress the components, and identify potential failure mechanisms. These tests may include temperature cycling, thermal shock, humidity testing, vibration testing, and electrical stress tests, among others.

Consumables

SiSTEM Technology specialises in top-quality spares and consumables for the semiconductor and high-tech manufacturing sectors. We offer a wide range of products, from Preventive Maintenance Spares Kits and Furnace Elements to Chuck Cleaning Wafers and Vacuum Traps & Filters, and much more.

At SiSTEM Technology our unwavering commitment lies in understanding your unique challenges to deliver honest and effective solutions while staying within budget.

With us, you gain a dedicated team that goes the extra mile to ensure your success, fostering a long-lasting and prosperous partnership.