Thermco Systems design and manufacture furnace systems, custom wet benches, epitaxy reactors, and electronic materials management equipment for the semiconductor, MEMS, LED, PV, and nanotechnology industries.

Our talented team of engineers are innovative in their design of a range of products to meet customer needs.

Thermco continue to develop new solutions for horizontal and vertical furnaces, including full cassette-to-cassette automation, upgraded control boards, and advanced next generation control systems with full backward compatibility. Thermco’s R&D extends to all product solutions and we pride ourselves in offering customers cutting edge technology. As a quality assured ISO 9001 2015 company, Thermco is proud to offer excellent customer service and support to maximise equipment uptime and low cost of ownership, synonymous with the

Thermco brand.

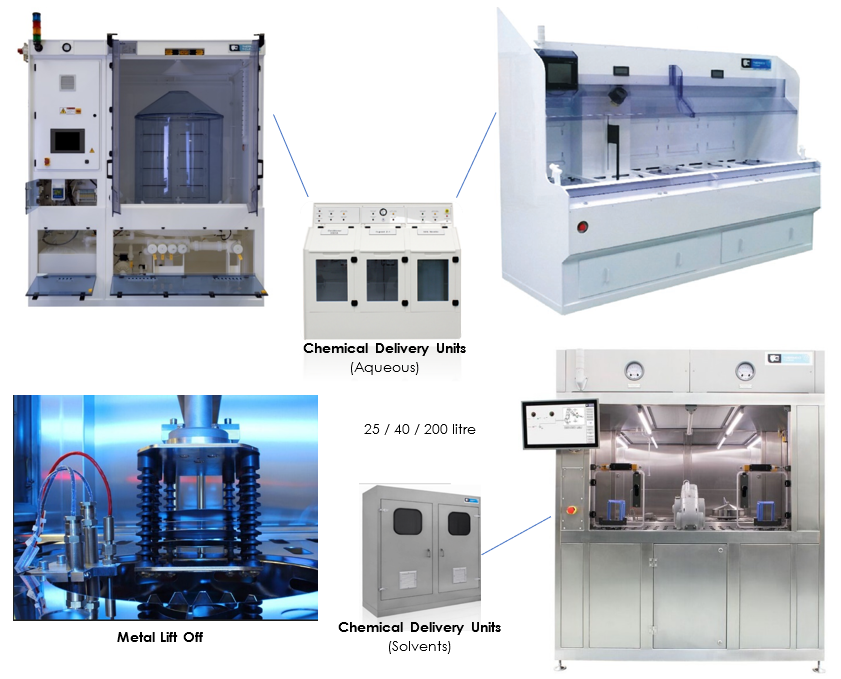

Thermco’s in-house designed and manufactured Chemical Wet Bench solutions

-

Wet Bench solutions (Automatic or manual)

-

Quartz parts Cleaning solutions

-

BellJar / Tube / Boat

-

Optical Fibre Etching and Cleaning

-

Metal lift off tool

-

Reduced Surface Tension Dryer

-

Bespoke chemical solutions

-

Porous Si Etching systems

-

Pre-diffusion / RCA Clean

-

Single wafer cleaning

-

Chemical Delivery Units (Solvents & Aqueous)

-

Valve Manifold Boxes

-

Electroless metal deposition Au, Ni, Pd, Cu, Ag

-

SPM (Piranha), SC1, BHF (BOE) – DHF, SC2, QDR